Coil Matrix Pro - Advanced Data Acquisition System

Project Overview

Coil Matrix Pro is a professional desktop application built with WinUI 3, specifically designed for coiled tubing operations in the oil & gas industry. The application provides a comprehensive solution for real-time sensor monitoring, data recording, chart visualization, and report export in Excel and PDF formats.

The application integrates with Opto 22 SNAP UP1 ADS hardware for sensor data acquisition with various signal types (Digital Encoder ABC, Analog Standard, Digital Magnetic Pickup) and features a hardware ID-based licensing system for maximum security.

This is a proprietary software project with a private repository. This documentation focuses on system architecture and features without revealing implementation details.

Table of Contents

- Key Features

- System Architecture

- Hardware Integration

- User Interface

- Configuration Management

- Export Capabilities

- Installation & Deployment

- Security Features

- Database Schema

- Performance Optimization

- Troubleshooting

- Future Enhancements

Key Features

🎯 Real-time Sensor Monitoring

- Multi-sensor support: CT Speed, CT Depth, Wellhead Pressure, Fluid Rate, Fluid Stage

- Live data polling: Configurable interval (default 100ms)

- Connection status: Real-time connection indicator with auto-reconnect

- Data source flexibility: Support for hardware device (Opto 22) and dummy simulation mode

📊 Advanced Visualization

- Gauge Charts: Circular gauges for monitoring critical parameters with warning/critical zones

- Line Charts: Multi-axis time-series charts with custom color palette

- Fullscreen Mode: Dedicated fullscreen view for operational monitoring

- Main Display: Customizable box view with real-time value updates

💾 Data Recording & Playback

- Recording Controls: Start, Stop recording with automatic timestamps

- Playback Feature: Play, Pause, Stop for historical data review

- Speed Control: Adjustable playback speed (1x, 2x, 5x, 10x)

- Database Storage: SQLite for efficient local data storage

📋 Configuration Management

- Device Configuration: Setup Opto 22 SNAP connection (IP, Port, Timeout)

- I/O Device Setup: Configure signal types and pin addresses for each sensor

- Encoder Configuration: PPR (Pulses Per Revolution) and Gear Ratio settings

- General Data: Customer info, well information, location, service data

- Chart Setup: Custom gauge and line chart configurations with color picker

📤 Export Capabilities

- Excel Export: ClosedXML integration for exporting readings with custom formatting

- PDF Reports: QuestPDF for generating professional chart reports

- Flexible Options:

- All readings vs current record only

- Chart report vs list/table report

- Custom column selection

- Auto-generated filenames with timestamps

🔐 Hardware License Validation

- Hardware-based Protection: License tied to unique hardware ID

- Anti-crack Strategy: Multi-layer validation system

- Installation Key: Secure key generation for installation

- Offline Operation: No internet connection required after activation

System Architecture

Technology Stack

Frontend Framework:

- .NET 8: Latest .NET framework for modern desktop development

- WinUI 3: Modern Windows UI framework with Fluent Design

Data Visualization:

- LiveCharts: Real-time chart rendering library

- Custom gauge implementations for industrial monitoring

Data Management:

- SQLite: Lightweight, embedded database for local storage

- Entity Framework Core for ORM

Export Libraries:

- ClosedXML: Excel file generation (.xlsx)

- QuestPDF: PDF report generation with custom layouts

Hardware Communication:

- Opto 22 SNAP Protocol: TCP/IP communication with industrial hardware

- Modbus TCP support

Packaging:

- MSIX: Modern Windows app packaging

- WiX Toolset v5 for MSI installer

- Inno Setup for traditional EXE installer

Component Architecture

The application follows a layered architecture pattern:

Presentation Layer (Views)

- Main monitoring interface

- Configuration dialogs

- Chart displays (Gauge, Line)

- Fullscreen views

Business Logic Layer (ViewModels & Services)

- Data acquisition service

- Database service

- Export service

- License validation service

- Configuration service

Data Access Layer (Models & Repositories)

- Entity models

- SQLite repositories

- Data transfer objects (DTOs)

Hardware Integration Layer

- Opto 22 SNAP communication

- Device abstraction interfaces

- Dummy data simulator

Data Flow Diagram

- Data Acquisition Flow:

- Hardware device → Communication service → Data processing → Storage

- Dummy simulator → Data generation → Storage

- Monitoring Flow:

- Database → Data retrieval → ViewModel → Live updates → UI components

- Export Flow:

- Database query → Data formatting → Export library → File generation

Hardware Integration

Opto 22 SNAP UP1 ADS

The application is designed to integrate with Opto 22 SNAP UP1 ADS, an industrial-grade data acquisition system that supports:

Communication Protocol:

- Ethernet/IP

- Modbus TCP

- TCP/IP with configurable port (default 2001)

Signal Types:

- Digital (Encoder ABC): For speed & depth measurement

- Quadrature encoder support

- A, B, A Complement, B Complement channels

- Configurable PPR (Pulses Per Revolution)

- Gear ratio settings

- Analog Standard: For pressure & flow sensors

- 4-20mA current loops

- 0-10V voltage inputs

- Configurable scaling

- Digital Magnetic Pickup: For fluid monitoring

- Frequency-based measurements

- Pulse counting

Connection Settings:

- Host/IP Address: e.g., 192.168.1.50

- Port: default 2001 (configurable)

- Timeout: 5000ms (adjustable for stability)

Sensor Configuration

Each sensor can be configured with:

- Tag name and description

- Signal type selection

- Pin address mapping

- Encoder-specific settings (PPR, Gear Ratio)

- Enable/disable toggle

User Interface

1. Splash Screen

The application launches with a professional splash screen displaying:

- Application logo

- Application name and tagline

- Loading indicator

- Clean, modern design

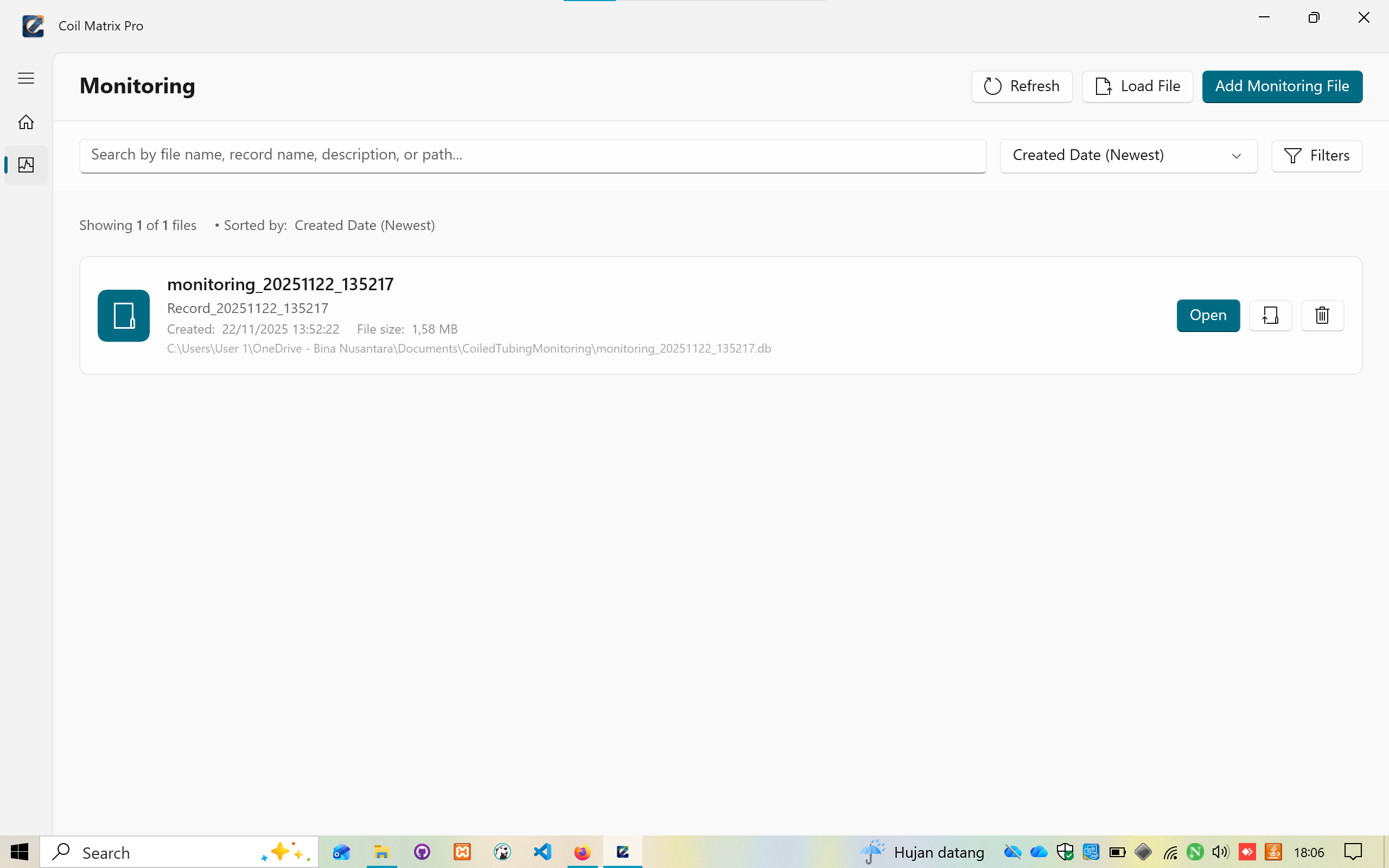

2. Monitoring Files Management

Features:

- Search functionality by file name, record name, description, or path

- Sort options (Created Date - Newest)

- Filters for advanced searching

- File information display:

- Record ID and timestamp

- File size

- Full file path

- Actions: Open, Load File, Add Monitoring File

- Refresh functionality

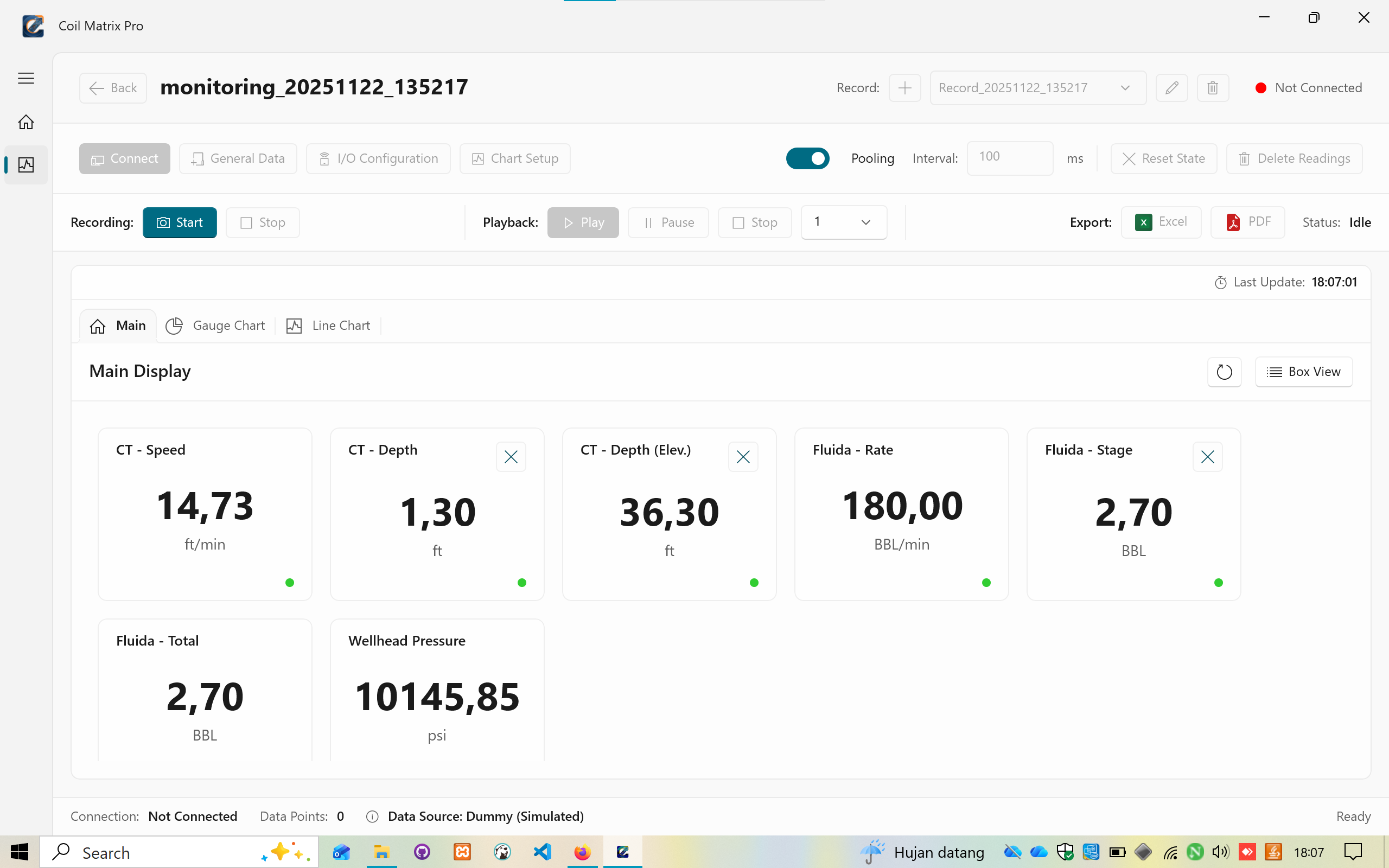

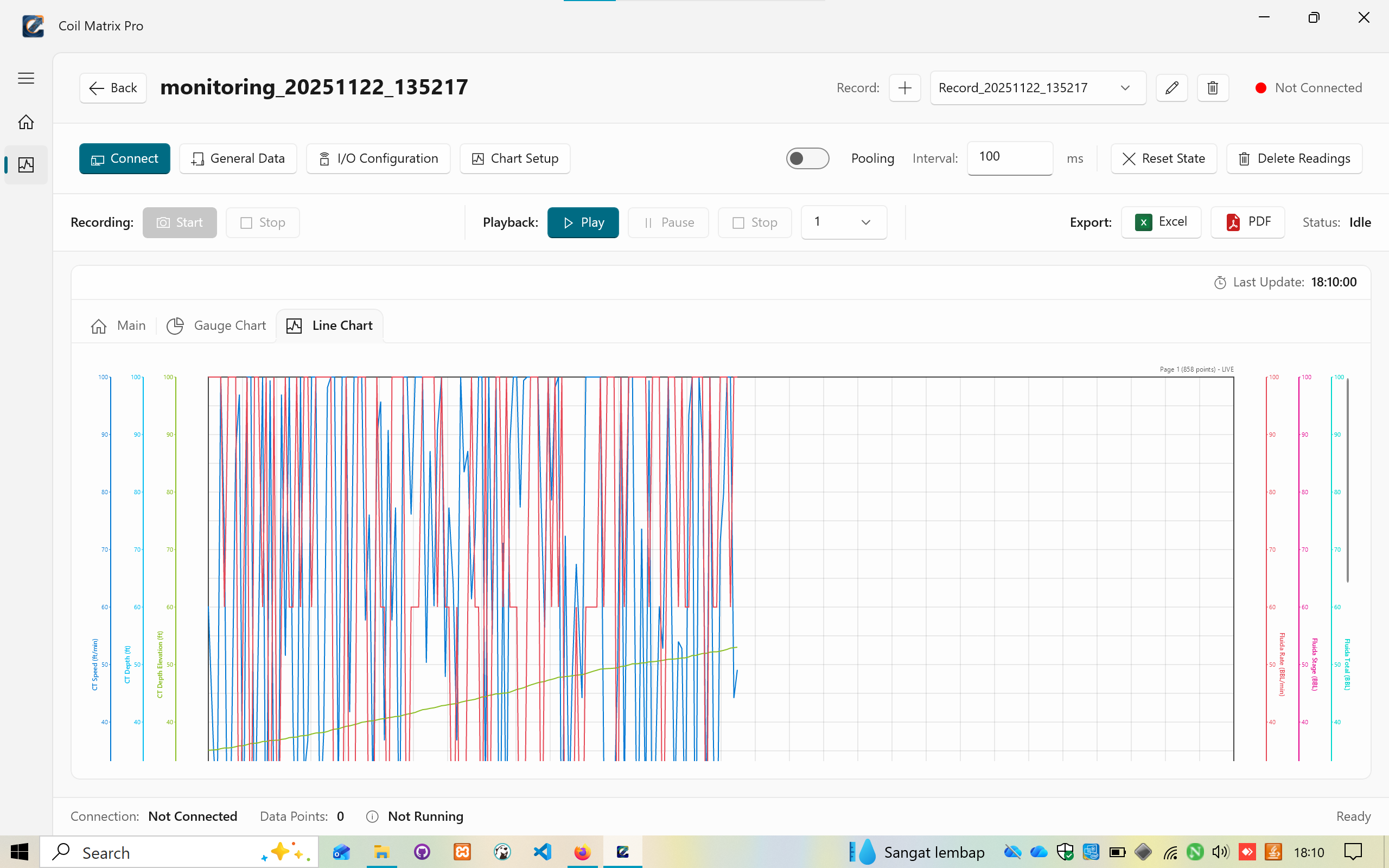

3. Main Monitoring Interface

The main interface displays real-time sensor values in a card/box view:

Sensor Cards:

- CT - Speed: Coil speed (ft/min) with status indicator

- CT - Depth: Current coil depth (ft)

- CT - Depth (Elev.): Depth with elevation (ft)

- Fluida - Rate: Fluid flow rate (BBL/min)

- Fluida - Stage: Fluid volume stage (BBL)

- Fluida - Total: Total fluid volume (BBL)

- Wellhead Pressure: Wellhead pressure (psi)

Control Panel:

- Polling Toggle: ON/OFF switch

- Polling Interval: Configurable in milliseconds (default: 100ms)

- Recording Controls: Start/Stop buttons

- Playback Controls: Play, Pause, Stop with speed selector (1x, 2x, 5x, 10x)

- Export Buttons: Excel and PDF export

- Reset State: Clear current readings

- Delete Readings: Remove recorded data

Status Bar:

- Connection status

- Data points count

- Data source indicator (Hardware/Dummy)

- Last update timestamp

- Application status (Ready/Idle)

Navigation Tabs:

- Main Display

- Gauge Chart

- Line Chart

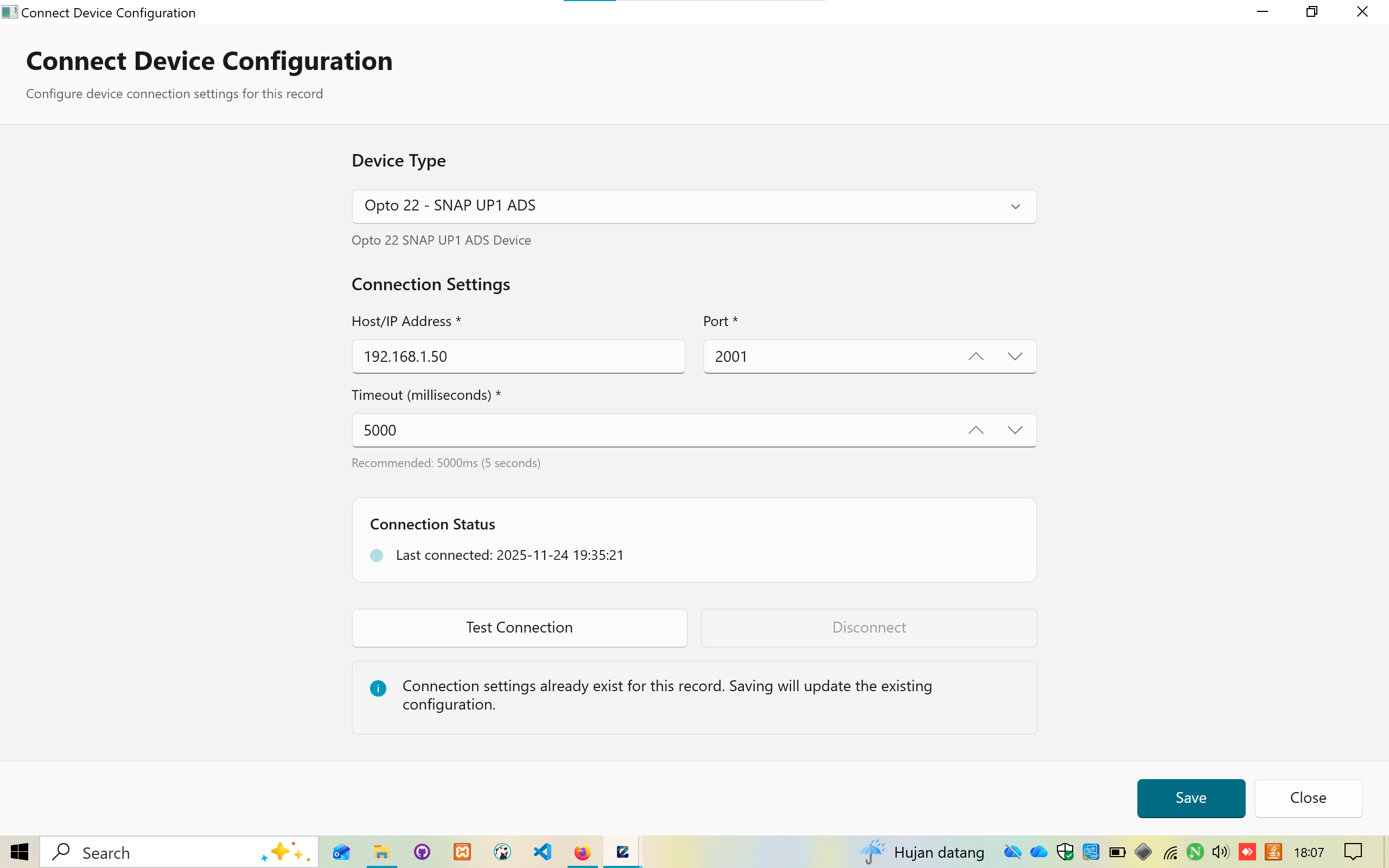

4. Connect Device Configuration

Configuration Options:

- Device Type: Dropdown selection (Opto 22 - SNAP UP1 ADS)

- Host/IP Address: Input field for device IP (e.g., 192.168.1.50)

- Port: Configurable port number (default: 2001)

- Timeout: Timeout in milliseconds (default: 5000ms)

- Recommended: 5000ms (5 seconds)

Features:

- Connection Status display with timestamp

- Test Connection button

- Disconnect option

- Save/Close buttons

- Information message for existing configurations

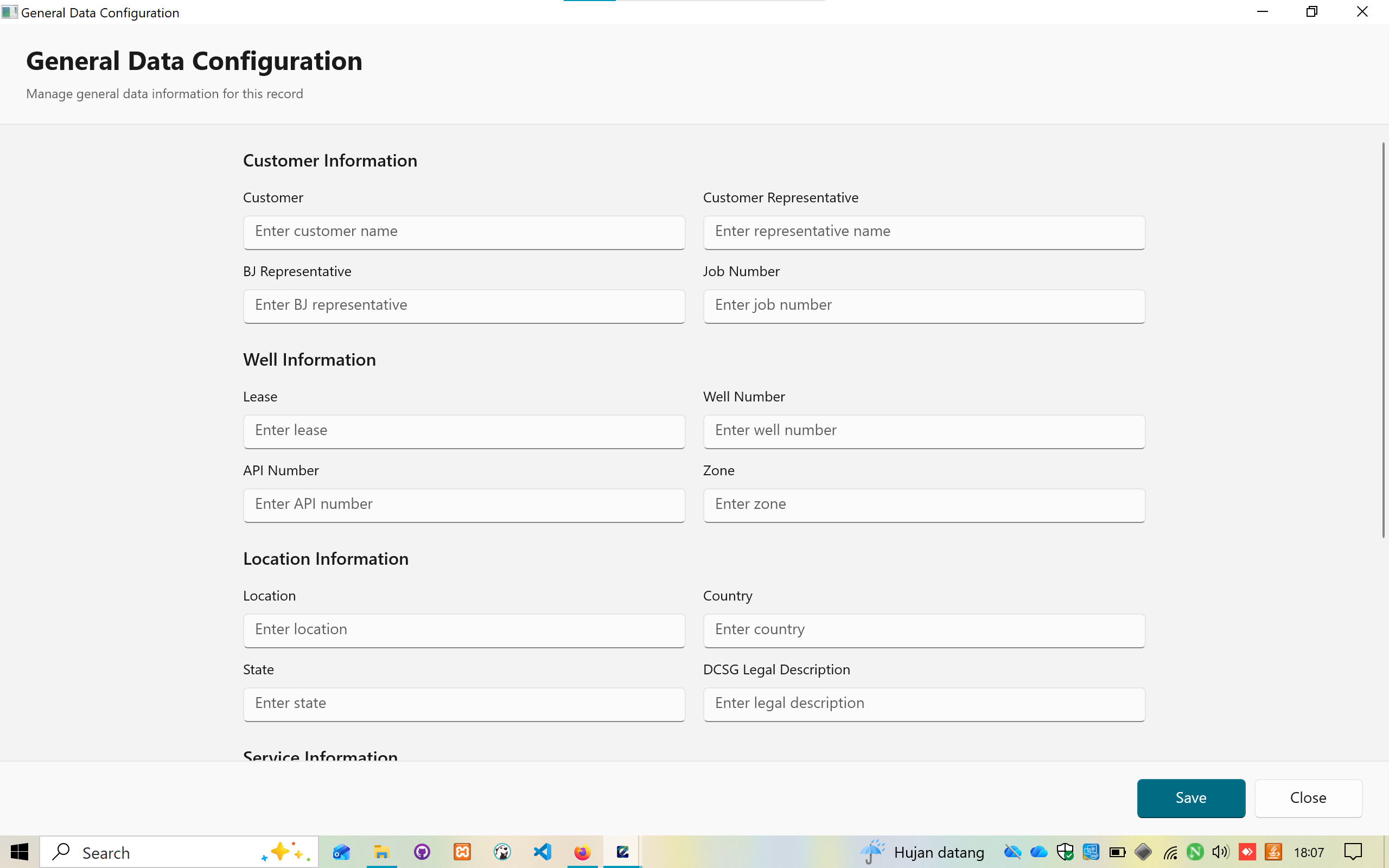

5. General Data Configuration

Comprehensive data entry form organized in sections:

Customer Information:

- Customer name

- Customer representative

- BJ representative

- Job number

Well Information:

- Lease name

- Well number

- API number

- Zone/formation

Location Information:

- Location (field)

- Country

- State/province

- DCSG Legal Description

Service Information:

- Service start date

- Service end date

- Service type

- Equipment details

All fields are text inputs with clear labels and placeholders.

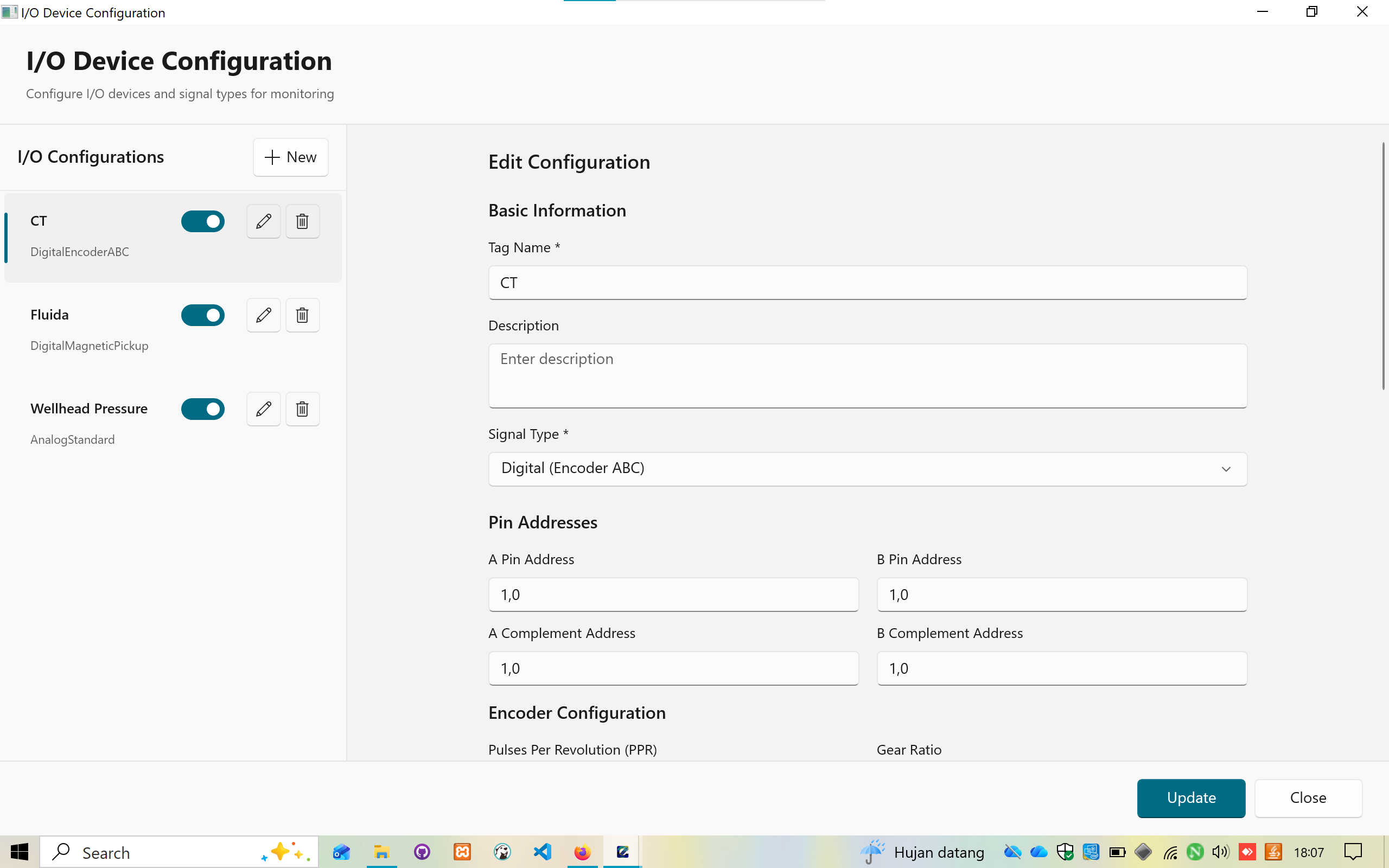

6. I/O Device Configuration

List-based configuration interface for each sensor:

Configuration List (Left Panel):

- CT - DigitalEncoderABC

- Fluida - DigitalMagneticPickup

- Wellhead Pressure - AnalogStandard

Each item has:

- Enable/disable toggle switch

- Edit button (pencil icon)

- Delete button (trash icon)

- Add New button to create additional sensors

Edit Configuration Panel (Right Side):

Basic Information:

- Tag Name (required field)

- Description (optional)

Signal Type Selection:

- Digital (Encoder ABC)

- Analog Standard

- Digital Magnetic Pickup

Pin Addresses:

- A Pin Address

- B Pin Address

- A Complement Address

- B Complement Address

Encoder Configuration:

- Pulses Per Revolution (PPR)

- Gear Ratio

Actions:

- Update button to save changes

- Close button to exit

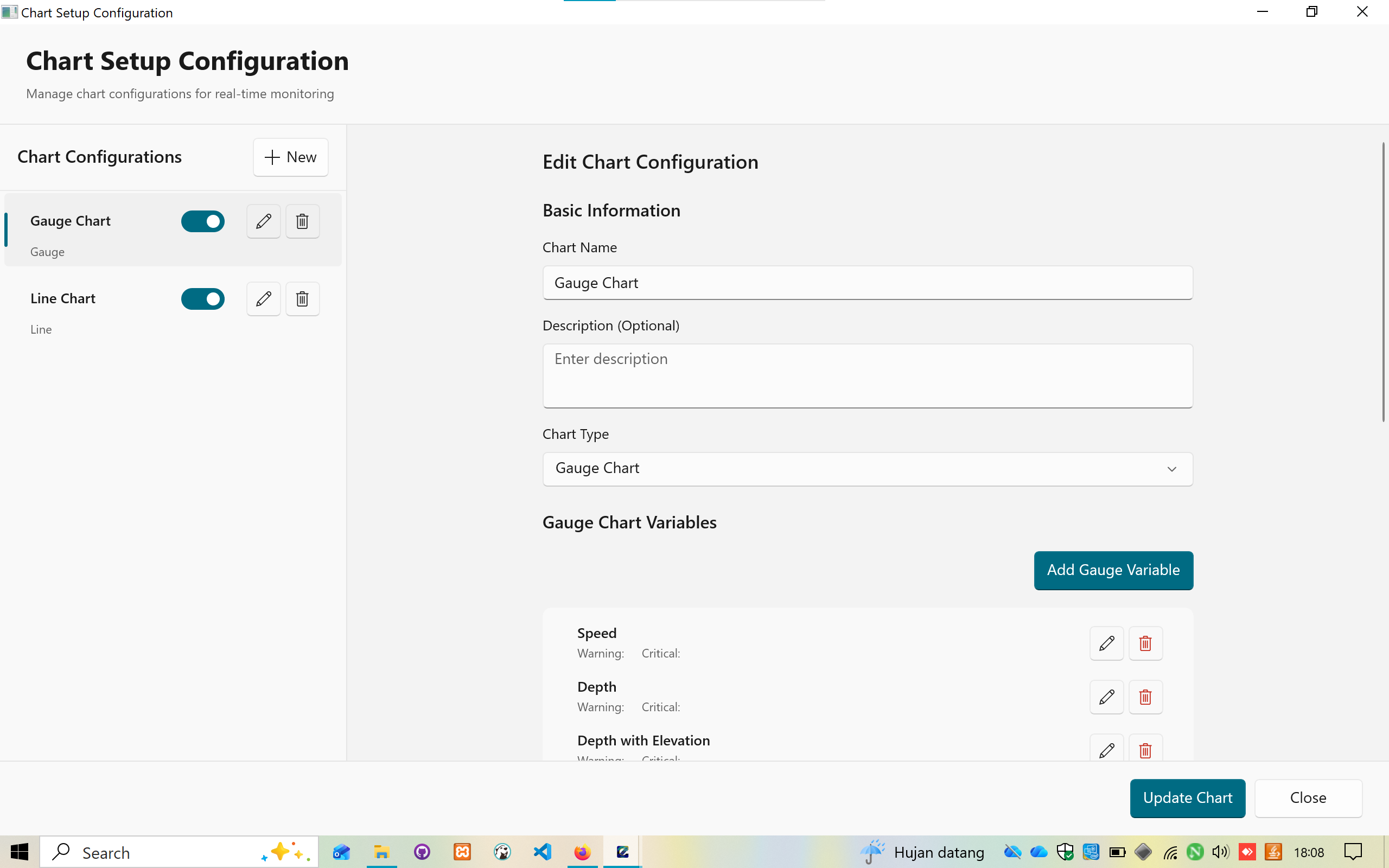

7. Chart Setup Configuration - Gauge

Left Panel - Chart Configurations:

- Gauge Chart (active)

- Line Chart

- Add New button

Right Panel - Edit Chart Configuration:

Basic Information:

- Chart Name

- Description (Optional)

- Chart Type dropdown (Gauge Chart / Line Chart)

Gauge Chart Variables:

- Add Gauge Variable button

- List of configured variables:

- Speed (Warning, Critical thresholds)

- Depth (Warning, Critical thresholds)

- Depth with Elevation (Warning, Critical thresholds)

- And more...

Each variable has:

- Edit button (pencil icon)

- Delete button (trash icon)

Actions:

- Update Chart button

- Close button

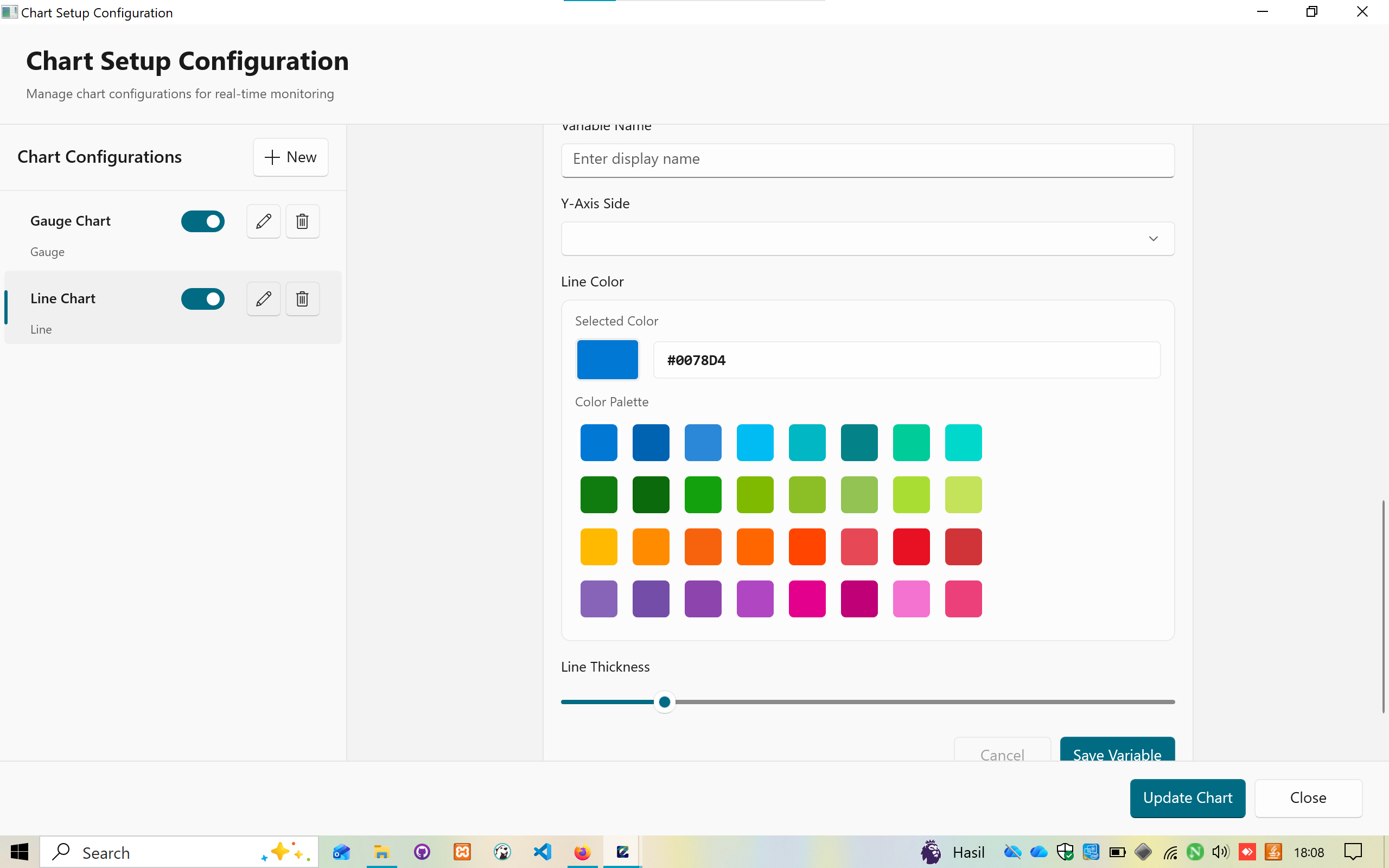

8. Chart Setup Configuration - Line Chart

Line Chart Variable Configuration:

Variable Settings:

- Variable Name field

- Display name input

- Y-Axis Side selection (Left/Right)

Line Color Picker:

- Selected Color display with hex code (#0078D4)

- Color Palette grid with 40+ colors:

- Blues (various shades)

- Greens (various shades)

- Yellows and oranges

- Reds and pinks

- Purples and magentas

Line Thickness:

- Slider control for adjusting line width

- Visual preview of thickness

Actions:

- Save Variable button

- Cancel button

- Update Chart button

- Close button

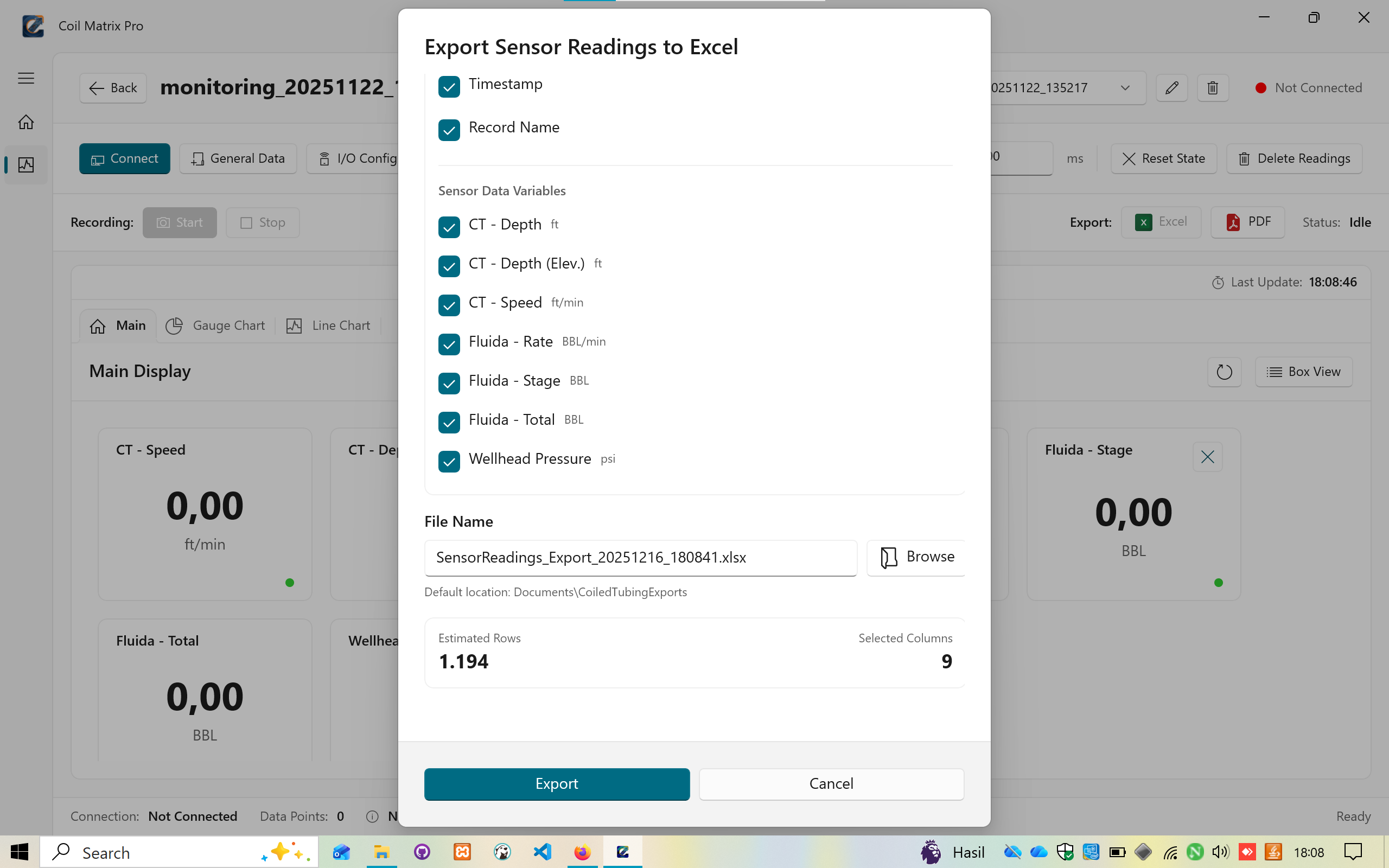

9. Export to Excel Dialog

Export Sensor Readings to Excel

Column Selection:

- Timestamp (checkbox)

- Record Name (checkbox)

Sensor Data Variables:

- CT - Depth (ft)

- CT - Depth (Elev.) (ft)

- CT - Speed (ft/min)

- Fluida - Rate (BBL/min)

- Fluida - Stage (BBL)

- Fluida - Total (BBL)

- Wellhead Pressure (psi)

All variables are selectable via checkboxes.

File Name:

- Auto-generated filename:

SensorReadings_Export_20251216_180841.xlsx - Browse button for custom location

- Default location: Documents\CoiledTubingExports

Export Information:

- Estimated Rows: 1,194

- Selected Columns: 9

Actions:

- Export button (primary action)

- Cancel button

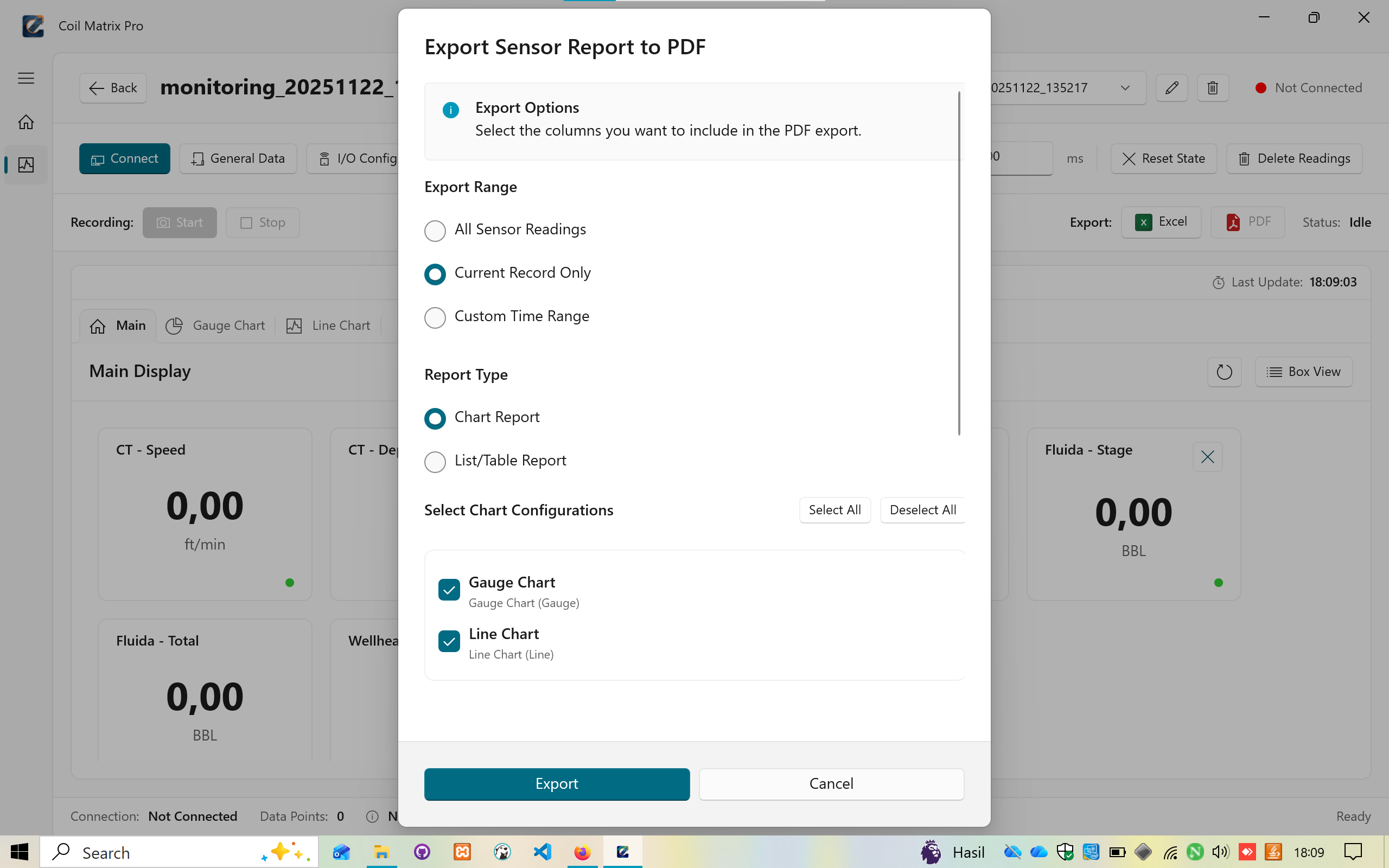

10. Export to PDF Dialog

Export Sensor Report to PDF

Export Range:

- All Sensor Readings (radio button)

- Current Record Only (radio button - selected)

- Custom Time Range (radio button)

Report Type:

- Chart Report (radio button - selected)

- List/Table Report (radio button)

Select Chart Configurations:

- Select All / Deselect All buttons

- Gauge Chart (checkbox - checked)

- Description: Gauge Chart (Gauge)

- Line Chart (checkbox - checked)

- Description: Line Chart (Line)

Actions:

- Export button (primary action)

- Cancel button

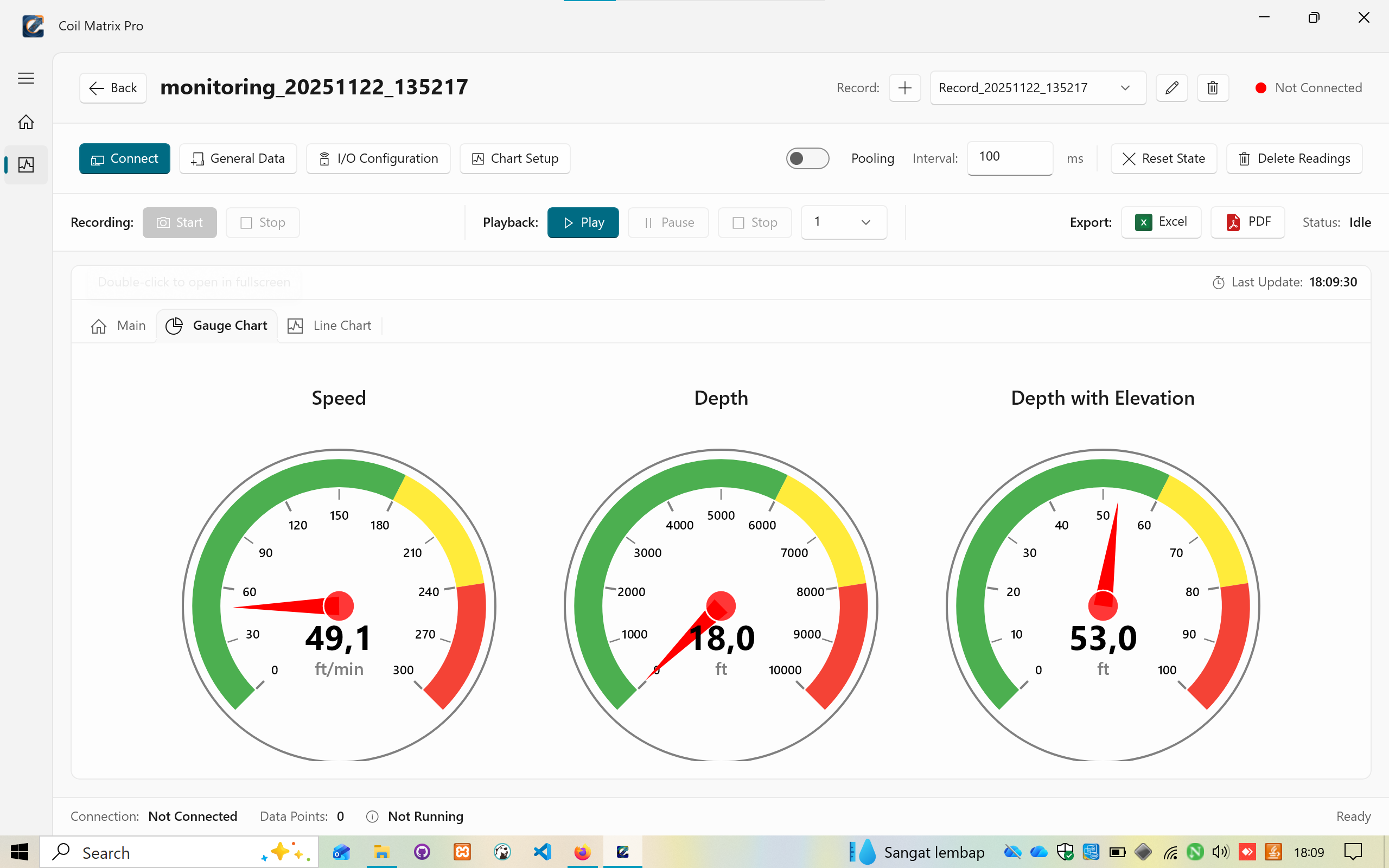

11. Gauge Chart View

Display Features:

- Three circular gauge charts in top row:

- Speed: 49.1 ft/min

- Depth: 18.0 ft

- Depth with Elevation: 53.0 ft

- Additional gauges in bottom row:

- Fluida: 180.0 (partially visible)

- Stage: 33.6 (partially visible)

Gauge Characteristics:

- Color-coded zones:

- Green: Safe operating range

- Yellow: Warning zone

- Red: Critical zone

- Large numeric display in center

- Unit labels below values

- Smooth needle animation

- Clean, professional design

Navigation:

- Double-click to open in fullscreen mode

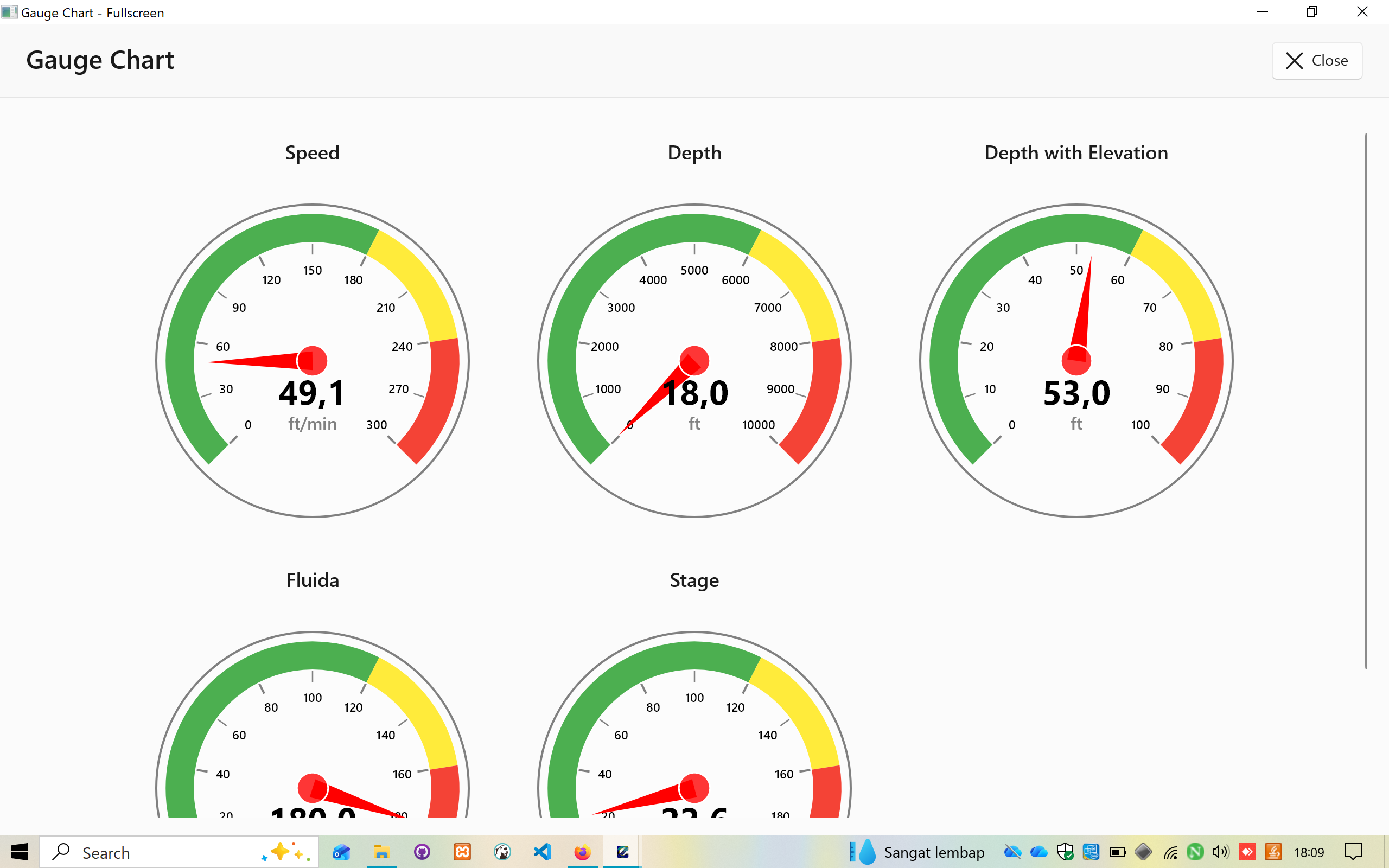

12. Gauge Chart - Fullscreen

Fullscreen Features:

- Header: "Gauge Chart"

- Close button (top right)

- Expanded view of all configured gauges

- Grid layout (3 columns)

- Visible gauges:

- Speed: 49.1 ft/min

- Depth: 18.0 ft

- Depth with Elevation: 53.0 ft

- Fluida: 180.0

- Stage: 33.6

- (Additional gauges below)

Perfect for:

- Operator monitoring stations

- Field operations displays

- Real-time supervision

- Dashboard presentations

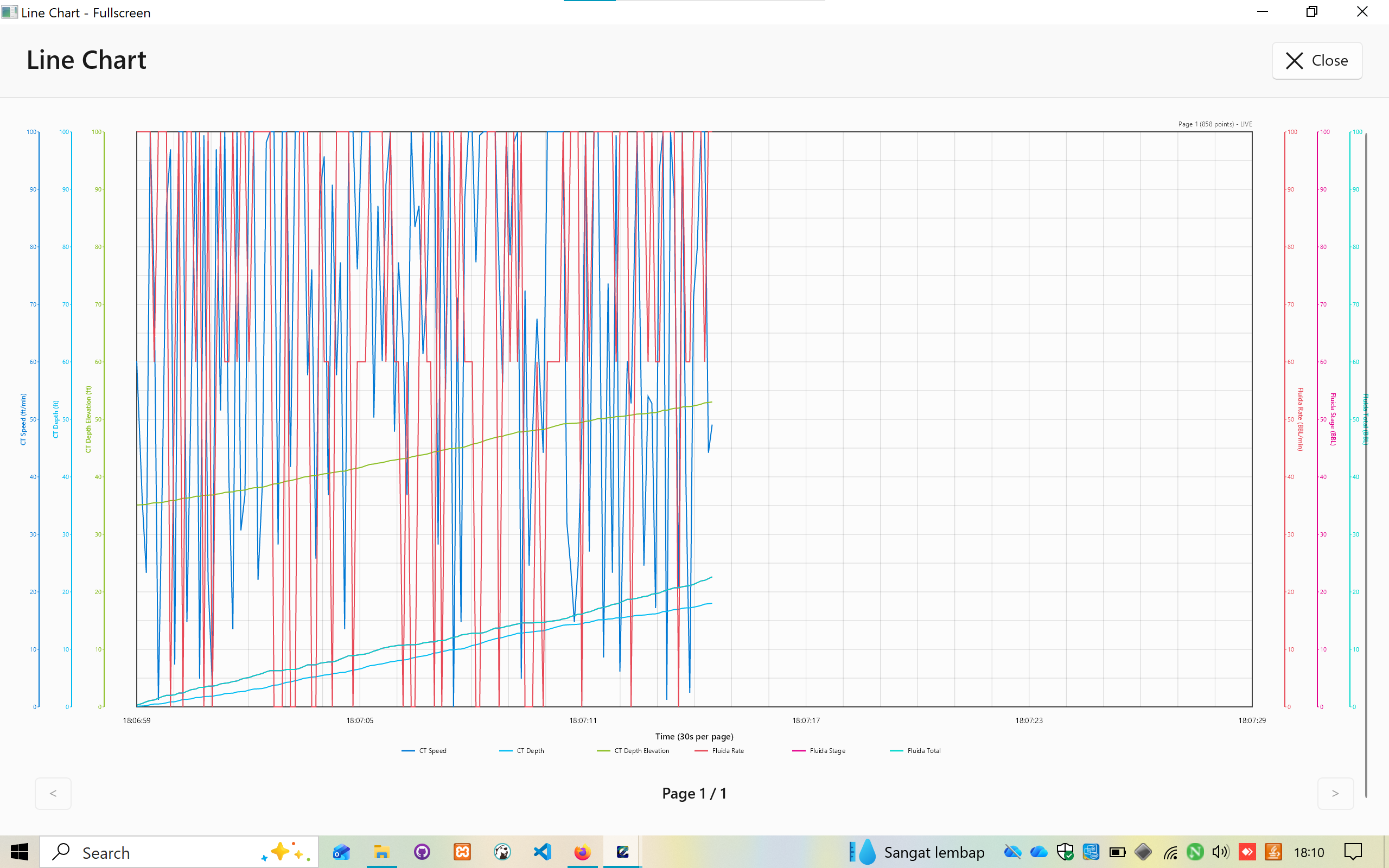

13. Line Chart View

Time-Series Chart Features:

- Multi-variable line display

- Dual Y-axis support (left and right)

- Color-coded lines:

- Blue shades for CT measurements

- Red shades for Fluida measurements

- Green for depth with elevation

- Additional colors for other variables

Chart Elements:

- Grid lines for easy reading

- Axis labels with units

- Legend showing all variables

- Page indicator: "Page 1 (858 points) - LIVE"

- Time range displayed on X-axis

Visible Variables:

- CT Speed (vertical spikes)

- CT Depth (increasing trend line)

- CT Depth with Elevation (parallel line)

- Fluida Rate (vertical variations)

- Fluida Stage (stepped increases)

- Fluida Total (cumulative line)

Navigation:

- Scroll for historical data

- Real-time updates in LIVE mode

- Pagination controls (if available)

14. Line Chart - Fullscreen

Expanded View Features:

- Full window chart display

- Clear time axis (30s per page default)

- Enhanced visibility of all data series

- Page navigation: "Page 1 of 1"

- Previous/Next buttons (< >)

Legend Display:

- CT Speed

- CT Depth

- CT Depth Elevation

- Fluida Rate

- Fluida Stage

- Fluida Total

Time Range:

- Displays timestamps on X-axis

- Example range: 18:06:59 to 18:07:29

Perfect for:

- Detailed data analysis

- Trend identification

- Historical playback review

- Report generation preparation

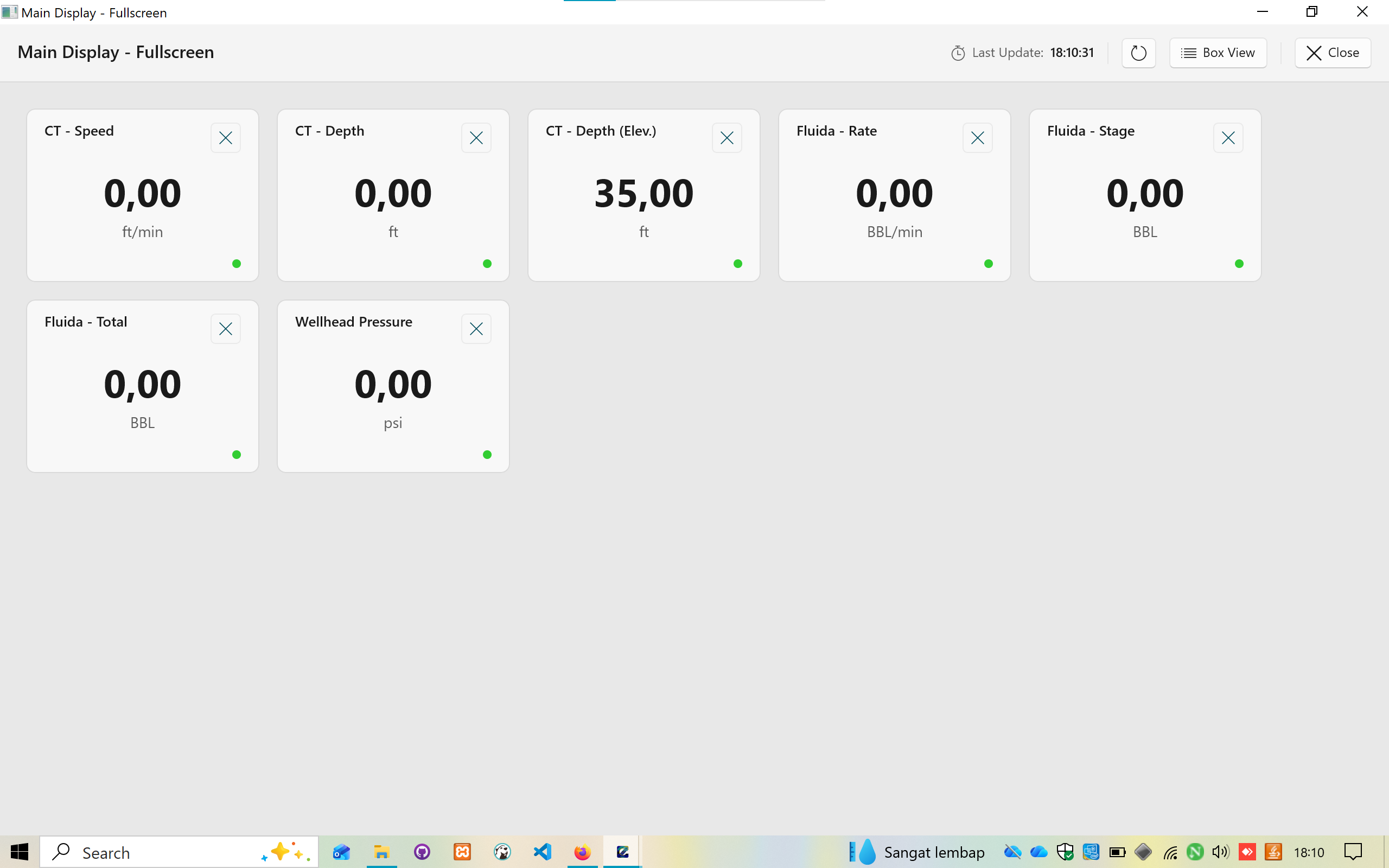

15. Main Display - Fullscreen

Fullscreen Box View:

- Large sensor value cards

- Clean, minimalist layout

- Easy-to-read values at a distance

Visible Sensor Cards:

- CT - Speed: 0.00 ft/min

- CT - Depth: 0.00 ft

- CT - Depth (Elev.): 35.00 ft

- Fluida - Rate: 0.00 BBL/min

- Fluida - Stage: 0.00 BBL

- Fluida - Total: 0.00 BBL

- Wellhead Pressure: 0.00 psi

Features:

- Status indicators (green dots)

- Remove card option (X button on each card)

- Last Update timestamp (18:10:31)

- Box View toggle

- Close button

Ideal for:

- Control room displays

- Field operation monitoring

- Large screen presentations

- Quick status overview

Configuration Management

Device Connection Setup

Purpose: Configure communication with Opto 22 SNAP UP1 ADS hardware

Steps:

- Click "Connect" button in main interface

- Select device type from dropdown

- Enter Host/IP Address

- Configure Port number

- Set Timeout value

- Click "Test Connection" to verify

- Save configuration

Best Practices:

- Use static IP addresses for hardware devices

- Increase timeout for networks with high latency

- Test connection before starting recording

- Document IP addresses for field deployment

General Data Entry

Purpose: Record job and well information for reports

Required Information:

- Customer and representative details

- Well identification (number, API, zone)

- Location data

- Service dates and equipment

Usage:

- Populated data appears in Excel/PDF exports

- Information stored per monitoring file

- Can be edited at any time

- Helps with record organization

I/O Device Configuration

Purpose: Define sensor connections and signal types

Configuration Process:

- Click "I/O Configuration" button

- Click "New" to add sensor

- Enter tag name and description

- Select signal type

- Configure pin addresses

- For encoders: set PPR and gear ratio

- Enable the sensor

- Click "Update" to save

Signal Type Guidelines:

Digital (Encoder ABC):

- Use for rotational speed measurement

- Requires A, B, A Complement, B Complement pins

- Must configure PPR and gear ratio

- Common for CT speed and depth

Analog Standard:

- Use for pressure and flow sensors

- Single pin configuration

- 4-20mA or 0-10V signals

- Scaling applied in software

Digital Magnetic Pickup:

- Use for frequency-based measurements

- Pulse counting for flow meters

- Single or dual pin configuration

Chart Setup

Gauge Chart Configuration:

- Click "Chart Setup" button

- Select "Gauge Chart" or create new

- Click "Add Gauge Variable"

- Select variable from I/O configuration

- Set Warning threshold

- Set Critical threshold

- Define Min/Max range

- Choose unit display

- Save variable

Color Zones:

- Green: 0 to Warning threshold

- Yellow: Warning to Critical threshold

- Red: Critical to Maximum

Line Chart Configuration:

- Select "Line Chart" from configurations

- Add variable

- Enter display name

- Choose Y-axis side (Left/Right)

- Select line color from palette

- Adjust line thickness

- Enable/disable in chart

- Save variable

Best Practices:

- Use left axis for similar-unit variables

- Use right axis for different-unit variables

- Choose contrasting colors for clarity

- Limit to 7 variables per chart for readability

Export Capabilities

Excel Export (ClosedXML)

Features:

- Professional formatting with headers

- Custom column selection

- Auto-generated filenames with timestamps

- Default export location: Documents\CoiledTubingExports

Export Structure:

Header Information (Sheet 1):

- Record metadata

- Customer information

- Well data

- Location details

- Service information

Readings Data (Sheet 2):

- Timestamp column

- Record name

- All selected sensor variables with units

- Color-coded columns

- Frozen header row

- Auto-width columns

Statistical Summary:

- Minimum values

- Maximum values

- Average values

- Calculated formulas

Export Options:

- All readings vs current record

- Column selection via checkboxes

- Estimated row count preview

- Selected columns count

- Browse for custom save location

PDF Report (QuestPDF)

Report Types:

1. Chart Report:

- Header with application logo

- Project and record information

- Gauge chart snapshots (grid layout)

- Line chart pages (multi-page support)

- Summary statistics table

- Page numbers and timestamps in footer

2. List/Table Report:

- Tabular data presentation

- Alternating row colors for readability

- Auto-pagination for large datasets

- Compact format

- Professional styling

Export Options:

- Export Range:

- All Sensor Readings

- Current Record Only

- Custom Time Range

- Report Type Selection:

- Chart Report (visual)

- List/Table Report (data-focused)

- Chart Configuration Selection:

- Select All / Deselect All

- Individual chart selection

- Gauge charts

- Line charts

PDF Styling:

- Custom fonts (Arial/Segoe UI)

- Professional margins and spacing

- High-quality chart rendering

- Brand-consistent color schemes

- Page headers and footers

Installation & Deployment

Build System

The project uses MSIX packaging for modern Windows app distribution.

Build Features:

- Code signing with certificate

- Automatic version incrementing

- Asset optimization

- Dependencies bundling

- One-click deployment

Installation Options

1. MSIX Package (Recommended)

- Modern Windows app package

- Double-click installation

- Automatic update support

- Clean uninstallation

- Windows Store ready

- App isolation and security

Advantages:

- Best user experience

- Automatic updates

- Clean installs/uninstalls

- Modern security model

Requirements:

- Windows 10 version 1809+ or Windows 11

- .NET 8 Desktop Runtime (bundled)

- 100 MB disk space

- 4 GB RAM minimum

2. WiX Installer (MSI)

- Traditional Windows installer

- Custom installation path

- Registry integration

- System-wide deployment

- Group Policy support

Use Cases:

- Enterprise deployment

- Custom installation paths

- System-wide configuration

- IT-managed environments

3. Inno Setup (EXE)

- Lightweight installer

- Customizable wizard

- Portable option available

- Legacy Windows support

- Minimal dependencies

Use Cases:

- Legacy system support

- USB stick deployment

- Offline installation

- Custom branding

System Requirements

Minimum:

- Windows 10 (Build 17763) or later

- .NET 8 Desktop Runtime

- 100 MB disk space

- 4 GB RAM

- 1280x720 display resolution

- Network adapter (for hardware connection)

Recommended:

- Windows 11

- 8 GB RAM

- SSD storage

- 1920x1080 display resolution

- Gigabit Ethernet for hardware communication

License Activation

Activation Process:

- Install Coil Matrix Pro

- Launch application

- Enter Installation Key when prompted

- Hardware ID automatically detected

- License validated

- Application activated

License Information:

- Tied to specific hardware ID

- Generated from: Motherboard + CPU + MAC Address

- Offline activation supported

- One-time activation per device

- No internet required after activation

License Types:

- Single Device: 1 hardware ID, lifetime updates

- Site License: Up to 10 devices, priority support

- Enterprise: Unlimited devices, custom features

Security Features

Anti-Crack Strategy

The application implements multi-layer protection:

1. Hardware ID Binding

- License tied to unique hardware identifier

- Generated from:

- Motherboard serial number

- CPU ID

- Primary MAC address

- Hash-based verification

- Prevents license sharing between devices

2. Code Obfuscation

- Critical sections obfuscated

- Anti-debugging techniques

- Control flow obfuscation

- String encryption

- Method name mangling

3. Integrity Checks

- Assembly verification at runtime

- Tamper detection mechanisms

- Checksum validation

- Digital signature verification

4. Encrypted Storage

- License keys encrypted with AES-256

- Database files protected

- Configuration files secured

- Sensitive data never in plain text

5. Online Validation (Optional)

- Periodic license server checks

- Revocation list support

- Stolen license detection

- Usage analytics (anonymous)

Protection Against:

- Key generators

- Crack patches

- Debug manipulation

- Memory editing

- Binary modification

- Virtual machine detection

Database Schema

SQLite Structure

Normalized Database Design

Tables:

1. MonitoringFiles

- FileId (Primary Key)

- FileName

- FilePath

- RecordName

- Description

- CreatedDate

- ModifiedDate

- FileSize

2. Records

- RecordId (Primary Key)

- FileId (Foreign Key)

- RecordName

- StartTimestamp

- EndTimestamp

- TotalDataPoints

- IsActive

3. SensorReadings

- ReadingId (Primary Key)

- RecordId (Foreign Key)

- Timestamp

- CTSpeed

- CTDepth

- CTDepthElevation

- FluidaRate

- FluidaStage

- FluidaTotal

- WellheadPressure

4. DeviceConfigurations

- ConfigId (Primary Key)

- RecordId (Foreign Key)

- DeviceType

- HostAddress

- Port

- Timeout

- LastConnected

5. IODevices

- DeviceId (Primary Key)

- RecordId (Foreign Key)

- TagName

- Description

- SignalType

- PinAddressA

- PinAddressB

- PinAddressAComplement

- PinAddressBComplement

- PPR

- GearRatio

- IsEnabled

6. ChartConfigurations

- ChartId (Primary Key)

- RecordId (Foreign Key)

- ChartName

- ChartType

- Description

- ConfigurationJSON

7. GeneralData

- GeneralDataId (Primary Key)

- RecordId (Foreign Key)

- CustomerName

- CustomerRepresentative

- BJRepresentative

- JobNumber

- LeaseName

- WellNumber

- APINumber

- Zone

- Location

- Country

- State

- DCSGLegalDescription

- ServiceStartDate

- ServiceEndDate

- ServiceType

- Equipment

Key Features:

- Foreign key constraints for referential integrity

- Indexes on frequently queried columns

- Timestamp indexing for performance

- RecordId indexing for fast lookups

- Transaction support (ACID compliance)

- Version-controlled schema migrations

Performance Optimizations:

- Batch inserts for recordings

- Connection pooling

- Query result caching

- Lazy loading for charts

- Indexed timestamps

Performance Optimization

Data Acquisition

Polling Strategy:

- Configurable interval (default 100ms)

- Balance between responsiveness and CPU usage

- Adaptive polling based on data rate

- Skip polling if no data changes

Threading Model:

- Background thread for data acquisition

- Async/await pattern throughout

- Non-blocking UI operations

- Thread-safe data structures

Buffer Management:

- Circular buffer for incoming data

- Prevents memory leaks in long recordings

- Configurable buffer size

- Automatic overflow handling

Database Operations

Write Optimization:

- Batch inserts (commit every 100 readings)

- Transaction batching

- Prepared statements

- Write-ahead logging (WAL mode)

Read Optimization:

- Connection pooling

- Query result caching

- Indexed columns for fast retrieval

- Pagination for large datasets

Query Examples:

-- Optimized for timestamp range queries

CREATE INDEX idx_readings_timestamp

ON SensorReadings(Timestamp);

-- Optimized for record lookups

CREATE INDEX idx_readings_recordid

ON SensorReadings(RecordId);

Chart Rendering

LiveCharts Performance:

- Hardware acceleration enabled

- GPU rendering when available

- Render throttling (max 60 FPS)

- Efficient data point updates

Data Decimation:

- Downsampling for large datasets

- Maintain visual accuracy

- Reduce rendering load

- Configurable decimation factor

Virtualization:

- Only render visible data points

- Lazy loading for historical data

- Viewport-based rendering

- Memory-efficient scrolling

Update Strategies:

- Incremental updates vs full redraw

- Dirty region tracking

- Batch update scheduling

- Animation frame optimization

Memory Management

Best Practices:

- Dispose resources properly

- Weak event handlers

- Unsubscribe from events

- Clear collections when done

- Use object pooling for frequent allocations

Monitoring:

- Built-in memory profiling hooks

- Leak detection in debug builds

- Performance counters

- Resource usage tracking

Troubleshooting

Common Issues

1. Device Connection Failed

Symptoms:

- "Not Connected" status indicator

- Unable to poll data from hardware

- Timeout errors

Possible Causes:

- Incorrect IP address or port

- Network firewall blocking connection

- Opto 22 device offline or not configured

- Timeout value too short for network latency

- Physical network cable disconnected

Solutions:

- Verify IP Address:

- Open command prompt

- Run:

ping 192.168.1.50(use your device IP) - Verify device responds

- Check Firewall Rules:

- Open Windows Firewall settings

- Allow port 2001 (or configured port)

- Add exception for Coil Matrix Pro

- Increase Timeout:

- Open Connect Device Configuration

- Increase timeout to 10000ms (10 seconds)

- Save and test connection

- Use Dummy Mode:

- Enable dummy simulation for testing

- Verify application functionality

- Isolate hardware vs software issues

- Check Hardware:

- Verify Opto 22 device power

- Check network cable connections

- Verify device configuration

2. Export Fails

Symptoms:

- Error message during export

- File not created

- Export process hangs

Possible Causes:

- File already open in Excel/PDF reader

- Insufficient disk space

- Invalid characters in filename

- Permissions issue on export folder

- Antivirus blocking file creation

Solutions:

- Close Existing Files:

- Close Excel or PDF reader

- Check Task Manager for hidden instances

- Retry export

- Check Disk Space:

- Verify available space on drive

- Clear temporary files if needed

- Export to different location

- Use Default Filename:

- Don't modify auto-generated filename

- Use default Documents\CoiledTubingExports folder

- Retry export

- Check Permissions:

- Ensure write permissions on export folder

- Try exporting to Desktop

- Run application as administrator (if needed)

- Disable Antivirus Temporarily:

- Temporarily disable real-time protection

- Retry export

- Add exception for Coil Matrix Pro

- Re-enable antivirus

3. License Activation Error

Symptoms:

- "Invalid License Key" message

- Application won't start

- License expired error

Possible Causes:

- Invalid installation key

- Hardware ID mismatch

- System clock incorrect

- Corrupted license file

- Hardware changes (motherboard, CPU, network card)

Solutions:

- Verify Installation Key:

- Check email for correct key

- Ensure no extra spaces when copying

- Use copy-paste instead of manual entry

- Contact support for key verification

- Check Hardware ID:

- Hardware changes invalidate license

- Re-generate hardware ID

- Request new license key for new hardware

- Sync System Time:

- Verify system date and time

- Enable automatic time synchronization

- Correct timezone settings

- Restart application

- Reinstall Application:

- Completely uninstall Coil Matrix Pro

- Delete residual files

- Reinstall from original installer

- Re-activate with installation key

- Contact Support:

- Provide hardware ID

- Provide error details

- Request new activation key

- Technical support available

4. Application Crashes or Freezes

Symptoms:

- Application stops responding

- Sudden crashes during operation

- Slow performance

Possible Causes:

- Insufficient memory

- Corrupted database file

- Conflicting software

- Driver issues

Solutions:

- Close Other Applications:

- Free up system memory

- Close unnecessary background apps

- Restart computer

- Check Database Integrity:

- Use SQLite database repair tools

- Backup database before repair

- Create new monitoring file if corrupted

- Update Drivers:

- Update graphics drivers

- Update network drivers

- Install Windows updates

- Reinstall .NET Runtime:

- Download .NET 8 Desktop Runtime

- Repair or reinstall runtime

- Restart computer

5. Charts Not Displaying

Symptoms:

- Blank chart areas

- Charts not updating

- Visual glitches

Possible Causes:

- Graphics driver incompatibility

- Hardware acceleration disabled

- Insufficient GPU memory

Solutions:

- Update Graphics Drivers:

- Download latest drivers from manufacturer

- Install and restart

- Test chart display

- Enable Hardware Acceleration:

- Check Windows graphics settings

- Enable GPU acceleration

- Restart application

- Reduce Chart Complexity:

- Limit number of variables

- Reduce line thickness

- Increase polling interval

6. Data Recording Issues

Symptoms:

- Recording doesn't start

- Data not saved to database

- Playback not working

Possible Causes:

- Database locked by another process

- Insufficient disk space

- File permissions

Solutions:

- Check Database Lock:

- Close other instances of application

- Ensure database file not open elsewhere

- Restart application

- Verify Disk Space:

- Ensure adequate free space

- Database grows with recording time

- Plan for long recording sessions

- Check File Permissions:

- Ensure write access to database location

- Move database to different folder if needed

- Run as administrator if required

Future Enhancements

Planned Features

Cloud Integration:

- Optional cloud backup for monitoring files

- Real-time data sync across devices

- Web-based dashboard for remote monitoring

- Cloud storage for historical data

Multi-language Support:

- English (default)

- Indonesian

- Arabic

- Spanish

- Chinese

Advanced Analytics:

- Statistical analysis tools

- Trend detection algorithms

- Predictive maintenance alerts

- Machine learning integration

- Anomaly detection

Mobile Companion App:

- Android and iOS applications

- Remote monitoring capabilities

- Push notifications for alerts

- Real-time data viewing

- Simplified controls

API Integration:

- REST API for third-party systems

- WebSocket for real-time updates

- Export API for automated reporting

- Integration with SCADA systems

- Custom plugin support

Enhanced Reporting:

- Report template builder

- Drag-drop report designer

- Custom branding options

- Scheduled automatic reports

- Email report delivery

Alarm System:

- Configurable threshold alarms

- Visual and audio alerts

- SMS/Email notifications

- Alarm history logging

- Escalation procedures

Advanced Playback:

- Timeline scrubbing

- Variable playback speeds

- Frame-by-frame navigation

- Bookmark important moments

- Export video of playback

Data Sync:

- Multi-device synchronization

- Conflict resolution

- Offline mode with sync

- Version control for configurations

Custom Export Templates:

- User-defined Excel templates

- Custom PDF layouts

- Branding customization

- Multiple template profiles

Technology Upgrades

Framework Upgrades:

- Migrate to .NET 9 (Long-term support)

- Upgrade WinUI 3 to latest stable version

- Implement .NET MAUI for cross-platform support

Communication Protocols:

- Implement gRPC for device communication (faster than TCP)

- Add MQTT support for IoT integration

- OPC UA for industrial automation standards

Real-time Features:

- Integrate SignalR for real-time web dashboard

- WebSocket support for live streaming

- Server-Sent Events (SSE) for updates

Machine Learning:

- ML.NET integration for predictive maintenance

- Pattern recognition for anomaly detection

- Automated threshold recommendations

- Failure prediction models

Performance:

- SIMD acceleration for data processing

- GPU compute for complex calculations

- Multi-threaded chart rendering

- Improved memory management

Security:

- OAuth 2.0 authentication for cloud features

- TLS 1.3 for encrypted communications

- Hardware security module (HSM) support

- Blockchain-based license management

Support & Licensing

Commercial License

Coil Matrix Pro is proprietary software requiring a paid license for production use.

License Types:

1. Single Device License

- Features:

- 1 hardware ID activation

- Lifetime software updates

- Email support

- Standard response time (24 hours)

- Access to documentation

- Bug fixes included

- Best For:

- Individual operators

- Single rig operations

- Testing and evaluation

- Small contractors

2. Site License

- Features:

- Up to 10 devices

- Lifetime software updates

- Priority support (4-hour response)

- Phone support included

- Custom training session

- Configuration assistance

- Quarterly check-ins

- Best For:

- Small to medium operations

- Multiple rigs at one site

- Growing companies

- Regional contractors

3. Enterprise License

- Features:

- Unlimited devices

- Lifetime software updates

- Premium support (1-hour response)

- 24/7 phone support

- Dedicated account manager

- Custom feature development

- On-site training

- Integration assistance

- Annual reviews

- Best For:

- Large corporations

- Multi-site operations

- International companies

- Custom requirements

Pricing:

- Contact for quotation

- Volume discounts available

- Multi-year agreements

- Flexible payment terms

Technical Support

Support Channels:

- Email Support: Available for all license types

- Phone Support: Site and Enterprise licenses

- Remote Desktop: For complex issues

- On-site Support: Enterprise license (additional fee)

Response Times:

Critical Issues (Application won't start, data loss):

- Single Device: 24 hours

- Site License: 4 hours

- Enterprise: 1 hour

High Priority (Major features not working):

- Single Device: 48 hours

- Site License: 8 hours

- Enterprise: 4 hours

Standard Issues (Minor bugs, questions):

- Single Device: 3 business days

- Site License: 24 hours

- Enterprise: 8 hours

Feature Requests:

- All licenses: Reviewed quarterly

- Enterprise: Priority consideration

Support Includes:

- Installation assistance

- Configuration guidance

- Troubleshooting

- Best practices advice

- Update assistance

- License management

Support Does NOT Include:

- Hardware troubleshooting (Opto 22 devices)

- Network infrastructure issues

- Operating system problems

- Third-party software conflicts

- Training on basic Windows operations

Updates & Maintenance

Bug Fixes:

- Free for all licensed users

- Released as needed

- Automatic update notification

- Optional automatic installation

Minor Updates (Feature additions, improvements):

- Included in all license types

- Released quarterly

- Backward compatible

- Optional installation

Major Versions (Significant rewrites):

- Major version upgrades may require upgrade fee

- Discounted pricing for existing customers

- Migration assistance included

- Data compatibility maintained

Security Patches:

- Always free for all users

- Released immediately when needed

- Strongly recommended installation

- May be automatically applied

Long-term Support:

- Each major version supported for 3 years

- Extended support available for Enterprise

- Security updates for 5 years

- Legacy version access maintained

Warranty & Disclaimers

Software Warranty:

- 90-day warranty against defects

- Replacement or refund if defective

- No warranty for misuse or modifications

Liability Limitations:

- Software provided "as-is" beyond warranty

- No liability for operational decisions based on data

- User responsible for data accuracy verification

- Maximum liability limited to license fee paid

Data Responsibility:

- User responsible for data backups

- User responsible for data accuracy

- User responsible for regulatory compliance

- Application is a tool, not a certified safety system

Best Practices

Operational Guidelines

Before Starting Operations:

- Test hardware connection

- Verify all sensors configured correctly

- Check gauge chart thresholds

- Ensure adequate disk space

- Create backup of previous data

- Document configuration settings

During Operations:

- Monitor connection status indicator

- Verify data is being recorded (Data Points count)

- Check Last Update timestamp regularly

- Monitor for warning/critical threshold breaches

- Use fullscreen mode for better visibility

- Keep application window focused for best performance

After Operations:

- Stop recording properly (don't force close)

- Export data to Excel/PDF immediately

- Backup database files

- Review data for anomalies

- Document any issues or notes

- Archive monitoring files properly

Data Management

File Organization:

- Use consistent naming conventions

- Include date and job number in filenames

- Organize by customer/well/date hierarchy

- Regular backups to external storage

- Cloud backup for critical data

Database Maintenance:

- Regular database optimization (monthly)

- Check database integrity periodically

- Archive old monitoring files

- Delete test/dummy recordings

- Monitor database file sizes

Export Strategy:

- Export immediately after recording

- Keep both Excel and PDF copies

- Store exports separately from database

- Use descriptive filenames

- Include metadata in exports

Configuration Management

Save Configurations:

- Document standard sensor setups

- Save common chart configurations

- Maintain configuration templates

- Version control configuration changes

- Share configurations across team

Backup Configurations:

- Export configuration settings

- Document custom thresholds

- Save device connection settings

- Keep configuration history

- Test configurations before deployment

Security Best Practices

License Management:

- Protect installation keys

- Document hardware IDs

- Track license assignments

- Report stolen devices immediately

- Maintain license inventory

Access Control:

- Restrict application access to operators

- Use Windows user accounts

- Protect database files

- Secure backup storage

- Monitor for unauthorized access

Network Security:

- Use private networks for hardware communication

- Implement firewall rules

- Use VPN for remote access

- Secure Wi-Fi if used

- Document network configuration

Performance Tips

Optimize Polling:

- Use appropriate polling intervals (100-500ms)

- Disable polling when not needed

- Reduce chart update frequency if sluggish

- Close unused fullscreen windows

- Limit number of active charts

System Resources:

- Close unnecessary applications

- Ensure adequate RAM available

- Use SSD for database storage

- Regular Windows maintenance

- Keep drivers updated

Data Recording:

- Start recording before operations begin

- Stop recording after operations complete

- Don't interrupt recording forcefully

- Monitor disk space during long recordings

- Use data decimation for very long recordings

Conclusion

Coil Matrix Pro represents a comprehensive, industrial-grade solution for coiled tubing operations in the oil & gas industry. The application successfully combines robust hardware integration, intuitive user interface design, and powerful data management capabilities into a single professional package.

Key Achievements

✅ Reliability

- Industrial-grade hardware support (Opto 22 SNAP UP1 ADS)

- Proven stable in field operations

- Automatic reconnection mechanisms

- Data integrity through SQLite ACID compliance

- Comprehensive error handling

✅ Performance

- Optimized for real-time data acquisition (100ms polling)

- Efficient database operations (batch inserts, indexed queries)

- Smooth chart rendering with hardware acceleration

- Low memory footprint

- Responsive UI even during intensive operations

✅ Security

- Multi-layer license protection system

- Hardware ID binding prevents piracy

- Encrypted storage for sensitive data

- Code obfuscation for critical sections

- Tamper detection mechanisms

✅ Usability

- Modern WinUI 3 interface with Fluent Design

- Intuitive configuration dialogs

- Fullscreen modes for field operations

- Clear status indicators and feedback

- Minimal training required

✅ Flexibility

- Configurable for various sensor types

- Support for multiple signal types (Digital, Analog)

- Customizable chart configurations

- Flexible export options

- Dummy simulation mode for testing

✅ Portability

- Export data in industry-standard formats (Excel, PDF)

- Professional reports with custom branding

- Comprehensive data export options

- Easy data sharing and archival

- Compatible with existing workflows

Industry Impact

Coil Matrix Pro has been designed with real-world field operations in mind:

- Operational Efficiency: Real-time monitoring enables immediate response to critical conditions

- Data Integrity: Reliable recording ensures complete operational records

- Regulatory Compliance: Comprehensive reports meet industry documentation requirements

- Cost Savings: Reduced data loss and improved decision-making

- Safety Enhancement: Warning thresholds and visual indicators improve operational safety

Technical Excellence

The application demonstrates strong software engineering principles:

- Modern Architecture: Clean separation of concerns with MVVM pattern

- Maintainability: Well-structured codebase with clear documentation

- Scalability: Designed to handle growing data volumes and feature additions

- Extensibility: Plugin-ready architecture for future enhancements

- Best Practices: Follows .NET and WinUI 3 development guidelines

Looking Forward

With planned enhancements including cloud integration, mobile companion apps, advanced analytics, and machine learning capabilities, Coil Matrix Pro is positioned to evolve alongside industry needs and technological advancements.

The application's solid foundation, combined with ongoing development and support, ensures it will remain a valuable tool for coiled tubing operations for years to come.

Contact Information

Developer: Fauzan Nur Hidayat

Company: Coil Matrix Pro

Year: 2025

License: Proprietary

Version: 1.0.0

For Sales & Licensing:

- Contact for quotation and licensing information

- Volume discounts available

- Custom feature development

- Enterprise agreements

For Technical Support:

- Email support included with all licenses

- Phone support for Site and Enterprise licenses

- Remote assistance available

- Comprehensive documentation provided

For Feature Requests:

- Submit via support channel

- Enterprise customers receive priority

- Quarterly review of all requests

- Custom development available

Appendix

Glossary

API Number: American Petroleum Institute well identification number

BBL: Barrel (42 US gallons), standard unit for oil and gas volumes

Coiled Tubing (CT): Continuous steel pipe wound on a reel for well intervention

DCSG: Surface location description format

Encoder ABC: Quadrature encoder with A, B, and complement channels

Fluida: Fluid (Indonesian term retained in application)

ft: Feet, unit of depth measurement

ft/min: Feet per minute, unit of speed

Lease: Oil and gas property under a single operator

MSIX: Modern Windows app packaging format

Opto 22 SNAP: Industrial I/O data acquisition system

PPR: Pulses Per Revolution, encoder configuration parameter

psi: Pounds per square inch, pressure unit

Wellhead: Surface equipment at the top of a well

Abbreviations

ADS: Analog and Digital System

API: Application Programming Interface (or American Petroleum Institute)

BJ: Baker Hughes (service company)

CSV: Comma-Separated Values

EXE: Executable file format

GUI: Graphical User Interface

I/O: Input/Output

IP: Internet Protocol

MSI: Microsoft Installer

MVVM: Model-View-ViewModel

ORM: Object-Relational Mapping

PDF: Portable Document Format

SCADA: Supervisory Control and Data Acquisition

SQL: Structured Query Language

TCP: Transmission Control Protocol

UI: User Interface

WinUI: Windows UI Library

XAML: Extensible Application Markup Language

Third-Party Licenses

Open Source Components:

- ClosedXML - MIT License

- LiveCharts - MIT License

- QuestPDF - Community License / Commercial License

- SQLite - Public Domain

- Additional NuGet packages - Various licenses

Commercial Components:

- .NET 8 - Microsoft

- WinUI 3 - Microsoft

- Windows App SDK - Microsoft

All third-party licenses are included in the installation and comply with respective terms.